Adjustable Reducing Standpipe KOR8/6L

Inhouse product

-

R214.00

-

R172.50

Reviews & Ratings

With the right fittings and accessories you can complete your lubrication system.

Applications:

- Single-line lubrication systems

- Dual-line lubrication systems

- Progressive lubrication systems

- Multi-line lubrication systems

- Small oil circulation systems

- Oil and air lubrication systems

- Minimal quantity lubrication systems

Single Line Systems

Regardless of the application, the principle of single-line lubrication remains the same: a central pump station automatically delivers lubricant through a single supply line to the lubricant metering device. Each metering device serves only one lubrication point. You can adjust to deliver the precise amount of grease or oil required. Systems can service one machine, different zones on one machine or even several separate machines.

Dual-line systems

Dual-line systems dispense a precise, metered amount of lubricant to up to 2 000 lubrication points over long distances up to 120 m (131 yd) and more. Even if one pair of outlets becomes blocked inside one metering device, dual-line systems provide sufficient lubrication for the rest of the system’s lubrication points. Lubricant volume can be metered individually for each pair of outlets and can be monitored visually or electrically.

Progressive systems

Progressive systems provide continuous lubrication as long as the pump is in operation. Once the pump stops, the pistons of the progressive metering device will stop in their current positions. When the pump starts supplying lubricant again, the pistons will carry on where they left. Therefore, the progressive circuit of one outlet of the pump will stop when only one lubrication point is blocked. The blockage serves as a means of control and forces personnel to service the system.

Related products

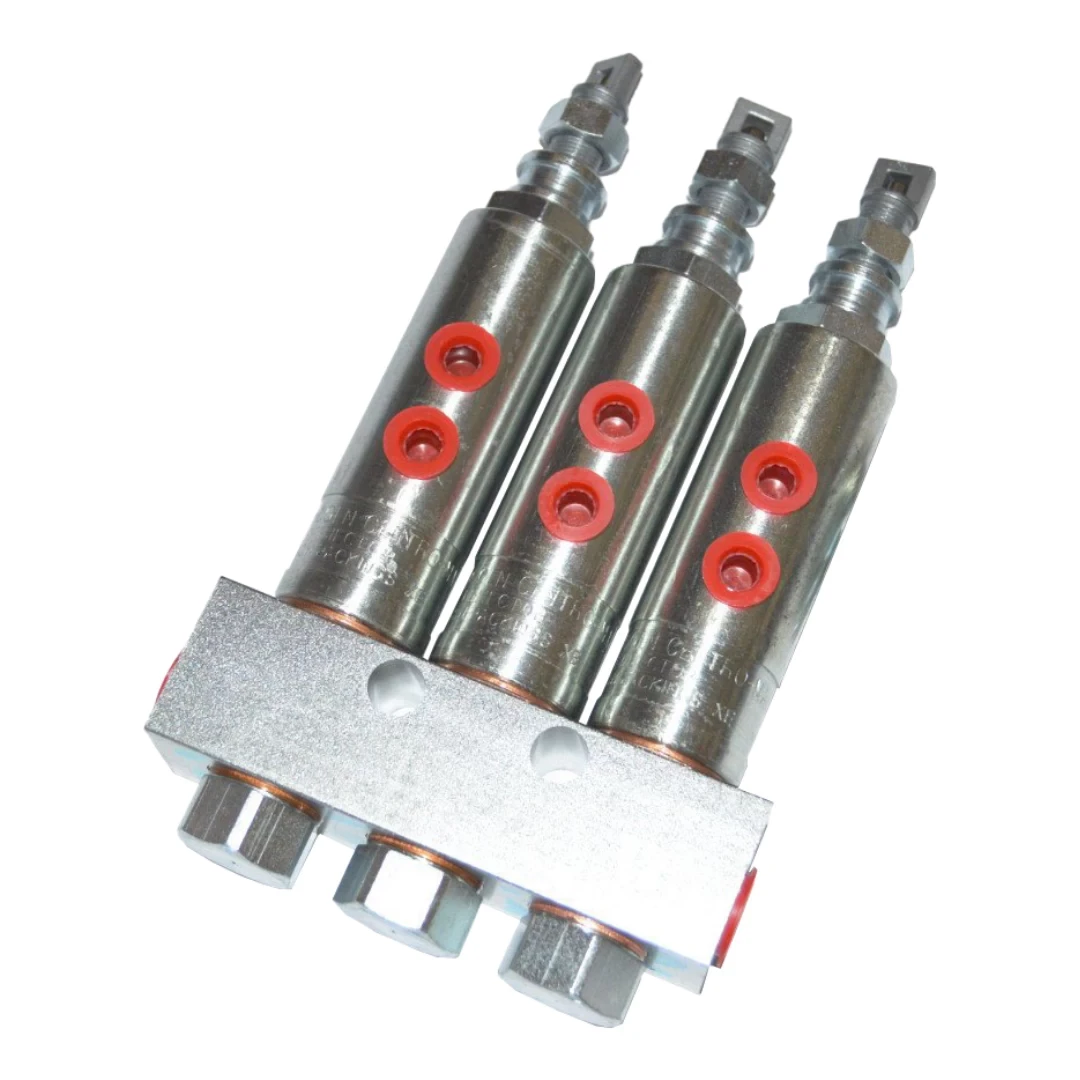

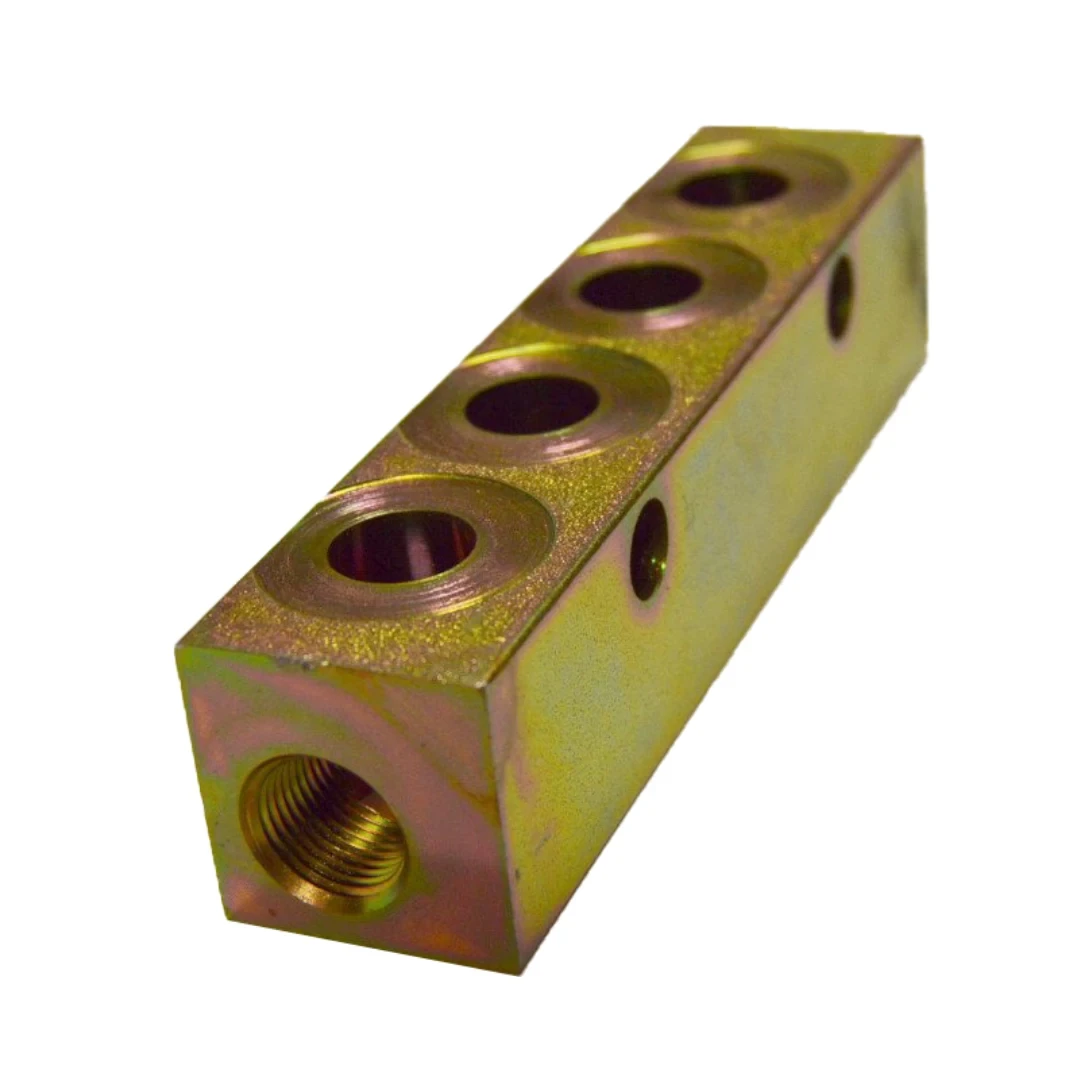

Injector, Single, SL-V

Manifold 3 Bank for Grease Injector SL-1

Manifold 2 Bank for Grease Injector SL-1

4 Bank Manifold SL-1 Manifold 4 Bank for Grease Injector SL-1

Manifold 6 Bank for Grease Injector SL-1

Manifold 5 Bank for Injector SL-1 & SL-V

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

R214.00

-

R172.50