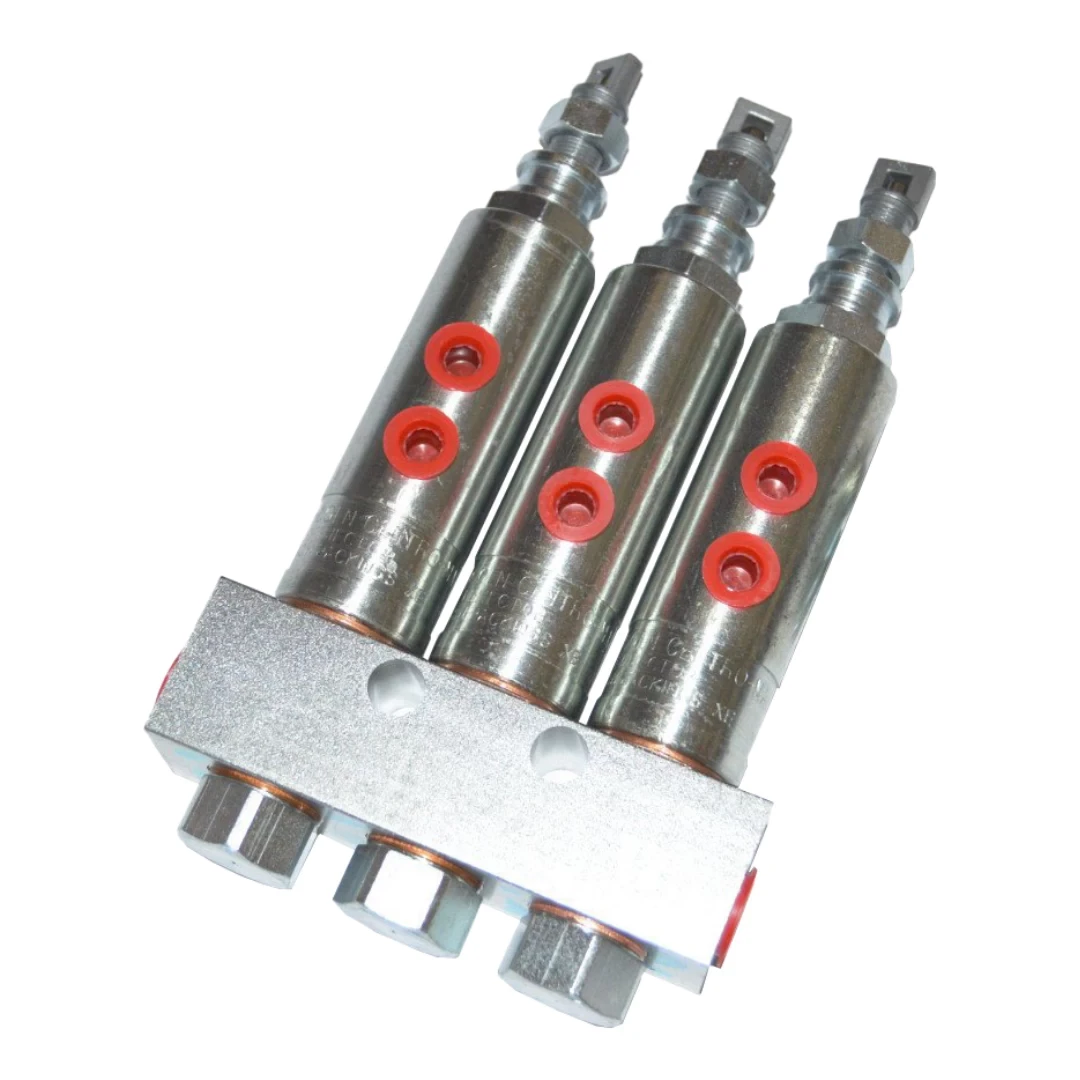

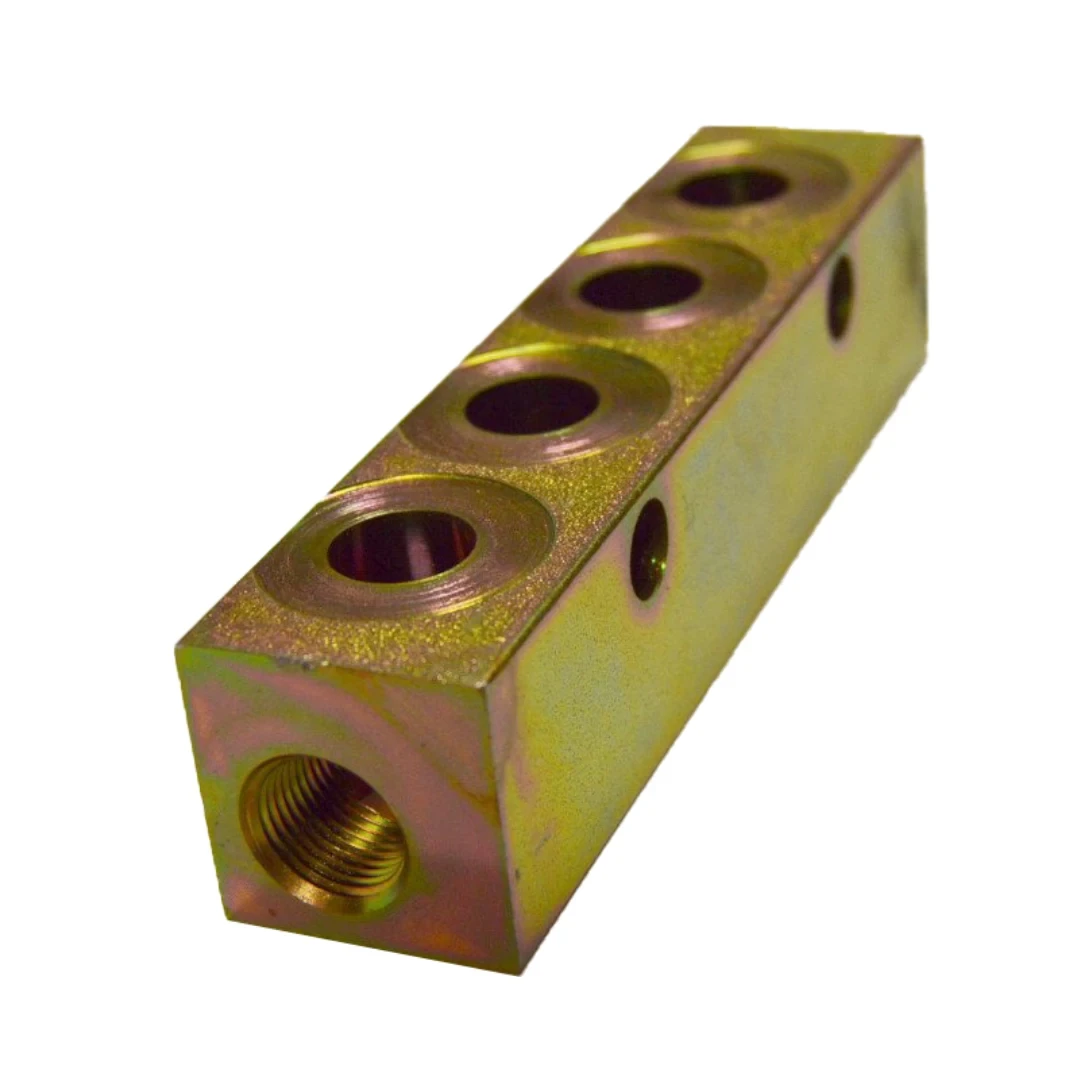

IPL Manifold 2 Way for I1 Grease Injector

Inhouse product

-

R214.00

-

R172.50

Reviews & Ratings

2 Way Injector Manifold for Automatic Lubrication Systems.

Automatic lubrication systems are key aspects in maintenance and reliability programs. They supply lubrication points with metered amounts of grease or oil from a central point. The pump feeds the system with the chosen lubricant. It is fed from a reservoir that is easily accessible. Depending on the application, the tank ranges in sizes. It can be as small as 2 liters all the way up to an intermediate bulk container. It can even be a bulk tank. The options are almost limitless and according to your needs and uses. You have the option to monitor these types of systems remotely with feedback. We can even tie it directly into your plant’s PLC (Programmable Logic Controller).

Whether you’re running an excavator, driving a ready-mix truck, operating a crusher, or making steel, you can rest assured that your assets are being properly lubricated at all times.

A single line parallel system can service a single machine or different zones on a single machine. It can even supply several separate machines. This type of system is ideal when the amount of lubricant is different for each point. In this type of system, a central pump station automatically delivers lubricant through a single supply line to multiple branches of injectors. Each injector serves a single lubrication point and operates independently. We can even adjust them individually to deliver the desired amount of lubricant.

How does it work?

Everything begins when the controller or timer sends a signal to the pump that starts the lube cycle. Then the pump begins pumping oil or grease to build up pressure in the supply line connecting the pump to the injectors. The lubrication injectors dispense the predetermined amount of lubricant to lubrication points via the feed lines under the right pressure.

Once the entire system reaches the required pressure, a pressure switch sends a signal to the controller indicating that grease has cycled through to all the distribution points. The pump shuts off. The system vents out pressure. Grease in the line is redirected back to the pump reservoir until the normal system pressure level is restored.

Auto lube systems have many advantages over traditional methods of manual lubrication:

- All critical components get lubricant. This is regardless of location or ease of access

- Lubrication occurs while the machinery is in operation, causing the lubricant to be equally distributed within the bearing and increasing the machine’s availability.

- Proper lubrication of critical components ensures safe operation of the machinery.

- Less wear on the components means extended component life, fewer breakdowns, reduced downtime, reduced replacement costs and reduced maintenance costs

- Measured lubrication amounts means no wasted lubricant

- Safety – no climbing around machinery or inaccessible areas (gases, exhaust, confined spaces, etc.)

- Lower energy consumption due to less friction

- Increased overall productivity resulting from increase in machine availability and reduction in downtime due to breakdowns or general maintenance.

Related products

Injector, Single, SL-V

Manifold 3 Bank for Grease Injector SL-1

Manifold 2 Bank for Grease Injector SL-1

4 Bank Manifold SL-1 Manifold 4 Bank for Grease Injector SL-1

Manifold 6 Bank for Grease Injector SL-1

Manifold 5 Bank for Injector SL-1 & SL-V

Manifold 2 Bank for Injector SL-1 & SL-V

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

R214.00

-

R172.50