Durable 1000gpm Industrial Water Pump for Heavy-Duty Applications3.

(0

reviews)

Estimate Shipping Time:

14 Days

Inhouse product

Price

R67,848.85

/each Incl. VAT

Share

Top Selling Products

-

R214.00

-

R172.50

Reviews & Ratings

0

out of 5.0

(0

reviews)

There have been no reviews for this product yet.

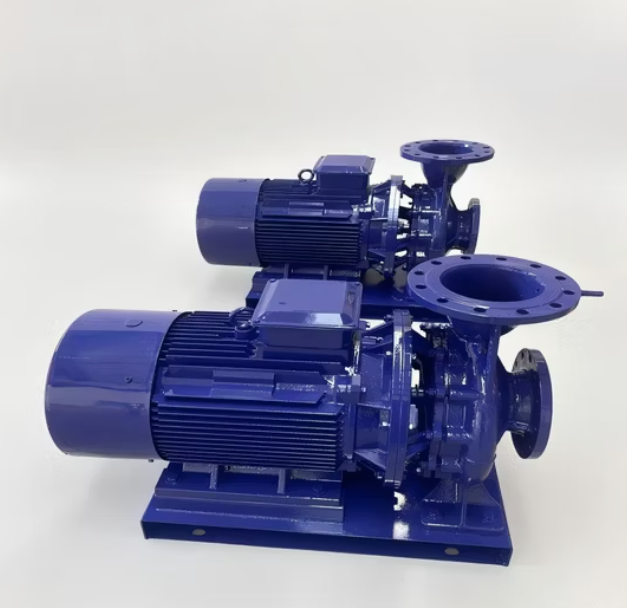

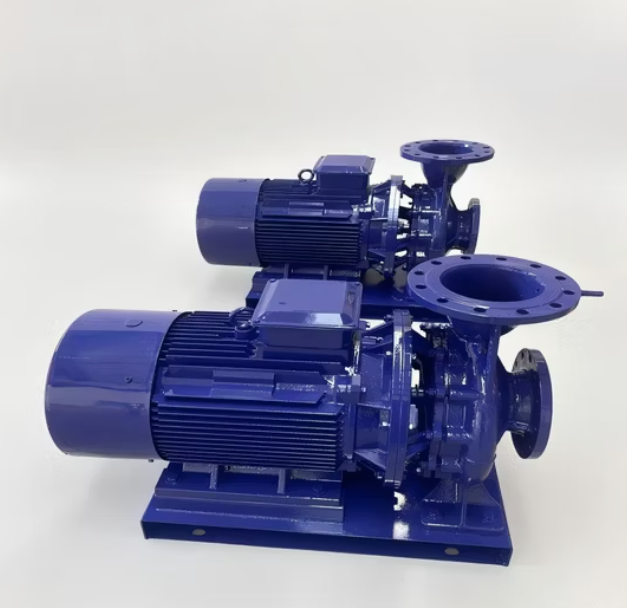

horizontal single-suction centrifugal pump

The horizontal structure allows for convenient on-site installation, as it requires less vertical space and simpler alignment with pipelines (compared to vertical pumps). For maintenance, key parts such as the impeller, mechanical seal, and bearing assembly can be accessed and disassembled without removing the entire pump from the pipeline, saving time and labor costs.

Applications

1.High-Rise Buildings & Super High-Rise Complexes

2. Large-Scale Industrial Facilities

3.Key Public Infrastructure

4.Large Commercial & Logistics Spaces

5.Hospitals, Schools & Temporary Water Supply

Key Configurations

1.High-Rise Buildings & Super High-Rise Complexes

2. Large-Scale Industrial Facilities

3.Key Public Infrastructure

4.Large Commercial & Logistics Spaces

5.Hospitals, Schools & Temporary Water Supply

Key Configurations

Typically made of cast iron, stainless steel (304/316), or bronze, depending on the corrosiveness of the conveyed medium.

Single-suction structure with optimized blade profiles (e.g., closed, semi-open) to ensure efficient conversion of mechanical energy into fluid kinetic energy, while reducing turbulence and energy loss.

Dynamic balance calibration is applied to minimize vibration during high-speed rotation (usually up to 3000 rpm for 50Hz power supply).

Adopts a volute-shaped design (spiral casing) that gradually expands the flow channel. Its main function is to collect the fluid discharged from the impeller, convert the fluid's kinetic energy into static pressure energy, and guide the fluid to the outlet pipeline smoothly.

Mechanical Seal: Composed of stationary and rotating rings (made of silicon carbide, tungsten carbide, or graphite). It offers excellent sealing performance (low leakage rate, ≤5mL/h) and long service life, suitable for clean or slightly contaminated media.

Related products

SPANJAARD OPEN GEAR LUBRICANT 6000 180KG

R65,440.00

High Pressure Small Displacement Light Dump Truck Lift Gear Pump

R13,309.00

R15,308.00

Electric Start 18 HP Diesel Engine 6 Inch Centrifugal Water Pump

R95,132.00

R99,800.00

MAC AFRIC Foot Shearer - Guillotine

R49,995.00

Homogenizer/Mixer/Emulsifier: 200L

R135,000.00

MAC AFRIC 4 Jaw Chuck for ELATHE/106

R5,995.00

MAC AFRIC 125 MM 4-Jaw Independent Chuck

R2,899.00

Top Selling Products

-

R214.00

-

R172.50